Training

Statistics training for your success

Knowledge of statistical methods forms the basis for production that meets the requirements of the latest guidelines and standards – from VDA Volume 5 and ISO 22514 to the MSA Manual and the SPC Manual from AIAG. We not only incorporate classic statistical methods, but also modern AI approaches. We will also be happy to advise you and find an individual approach that will lead your industrial production to success.

We analyse your individual use case and advise you in order to determine an approach that is perfectly tailored to you.

Our seminars are characterized by well-founded basic knowledge, specific applications and practical examples. See the variety of statistical topics for yourself.

Professional training for your team

In industrial production, several ISO standards form the basis for the capability analysis of measurement and test processes as well as machines, production facilities and assembly processes:

- ISO 22514 ff: Statistical Methods in Process Management – Capability and Performance

- ISO 7870 ff: Control Charts

- ISO 11462 ff: Guidelines for Implementation of Statistical Process Control (SPC)

These standards are now set out in guidelines from associations such as VDA (German Association of the Automotive Industry) and AIAG (Automotive Industry Action Group) have been incorporated. These include:

- the VDA 5 Volume Measurement and Test Processes

- the SPC manual from VDA and AIAG

The latter will be published as a joint document by the VDA and the AIAG in 2025 and will be used as referenced document for certification in accordance with IATF 16946 (International Automotive Task Force) in future.

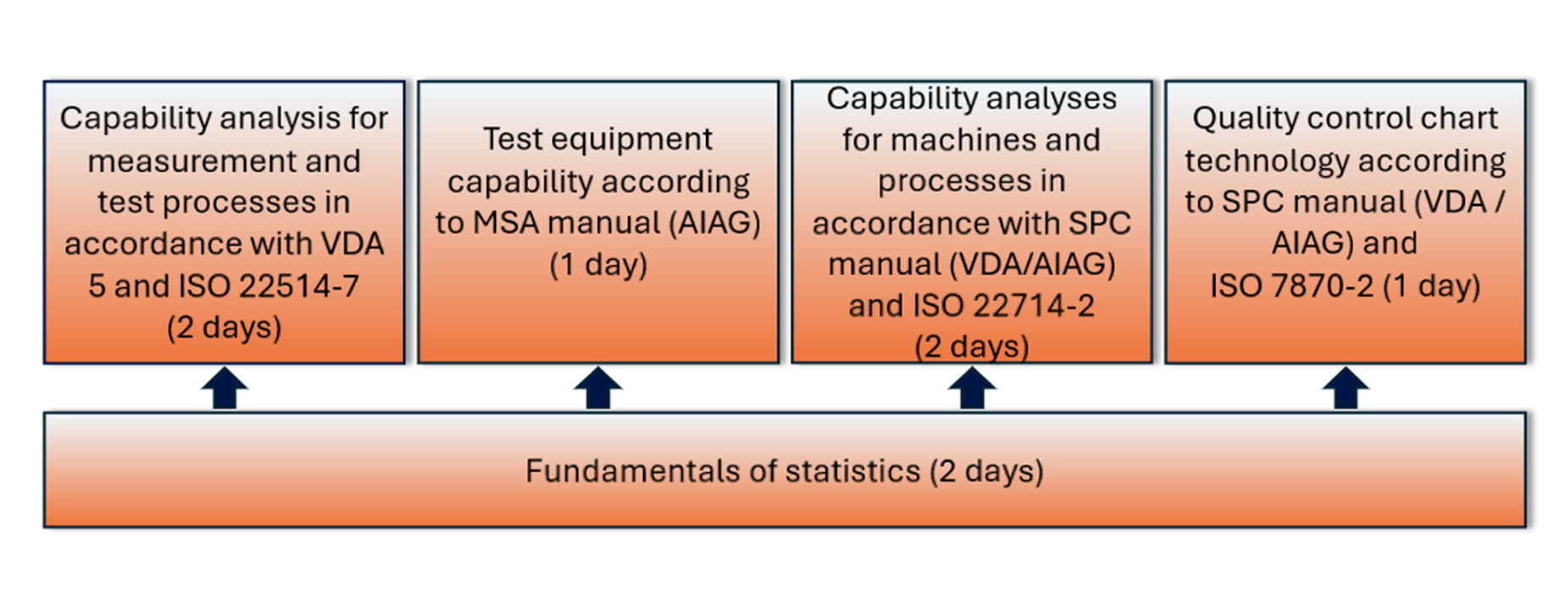

Fundamentals of statistics

In our two-day training course, you will learn the basic methods of statistics. The way of thinking when dealing with these methods plays a central role. We see these methods as a toolbox and explain when to use which tool, how to handle the respective tools and how to interpret the results.

Capability analyses for machines and processes in accordance with the SPC manual (VDA/AIAG) and ISO 22714-2

For new products or significant changes in production technology, a machine capability analysis is carried out to determine whether the equipment is suitable for the product to be manufactured. If this is the case, a process capability analysis is carried out to determine whether production remains stable under long-term conditions. This training course will provide you with the necessary knowledge.

Test equipment capability according to MSA manual (AIAG)

In order to assess the characteristics produced, SPC measuring stations have been established close to production for worker self-testing since the 1980s. For this purpose, the measuring devices used require capability analyses to prove their suitability for the specific application. The AIAG’s MSA manual, which has been continuously improved since then and forms the basis of many company guidelines, was a pioneer in this respect. Further parameters for evaluating the measuring system were introduced in a guideline of the German automotive industry. In this training course, we will familiarize you with the procedure.

Capability analysis for measurement and test processes in accordance with VDA 5 and ISO 22514-7

True to the motto “You can only manufacture as accurately as you can measure!”, the user must know the measurement uncertainty of the measurement and test process for each measured value in order to assess the value in relation to the specification limits. VDA Volume 5 and ISO 22514-7 contain the procedure for determining the measurement uncertainty. In addition, VDA Volume 5 explains how test process management works for a holistic approach. We impart all this knowledge to you in this training course.

Quality control chart technology according to SPC manual (VDA / AIAG) and ISO 7870-2

Once the capability for machines and processes has been successfully established, ongoing production must be continuously monitored in order to detect significant changes and, if necessary, intervene in the process to correct them in good time. This process control is carried out on a random basis using quality control charts. Learn how the quality control chart works and when which control chart is used.

Book individual consulting for your company now!

We will look at your individual application in a personal appointment. We gain an insight into your production processes, take your wishes and requirements into account and provide you with comprehensive advice in order to find a solution that is perfectly tailored to your needs.

Our methodological and practical knowledge enables us to develop a holistic concept for you that takes into account the need for training and the use of software or other aids.